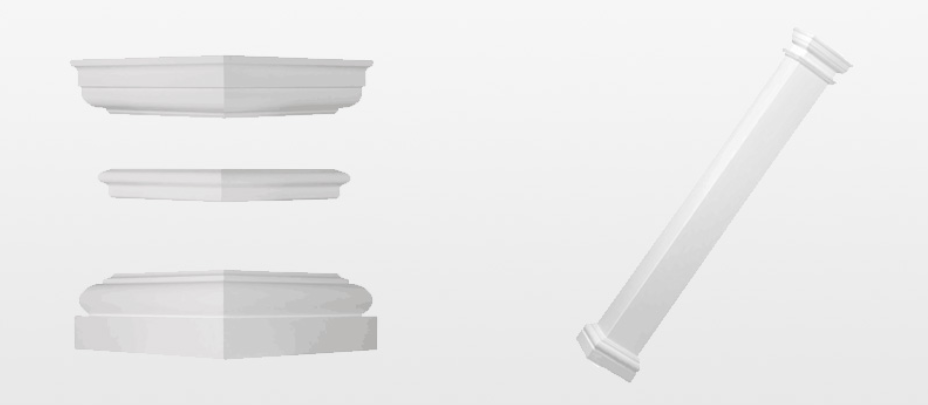

FRP column/post is made of a durable mixture of fiberglass and polymer resin. Commonly referred to as fiberglass reinforced polymer composite column/post, our FRP columns/posts are manufactured as structural columns, showing a seamless design and strong load-bearing capacity. And our FRP columns can be used in any outdoor space (including commercial and residential areas).

Compared with commonly used metal materials or gypsum, fiberglass column/post has the following characteristics:

1. Excellent Physical and Chemical Properties

FRP columns/posts have the characteristics of light weight, high strength, heat insulation, heat resistance, insulation, radiation resistance, corrosion resistance, electromagnetic wave penetration, and low temperature resistance, and can be used in many environments and fields. FRP is an anisotropic material, and its formula and additives have a wide range of selectivity, which can be adjusted artificially, so that its physical and chemical properties have more room for adjustment. Especially after the development of FRP plating technology and plateable FRP, the application field of FRP has been further expanded.

2. Broad Design Adaptability

FRP columns can be adapted to various design needs, and can be designed and manufactured according to different use environments and special performance requirements. As long as you choose suitable raw materials, you can basically meet the performance requirements of various products for different purposes. Therefore, FRP material is an excellent material variety with designability.

3. Excellent Formability

FRP posts can be processed in a variety of ways, so that processing methods suitable for products with different designs and different requirements can be easily selected. According to incomplete statistics, there are more than 30 processing methods. It can be made by hand or machined. And it can usually be formed at one time during the manufacturing process, which is another significant feature that distinguishes it from metal materials. As long as you select the appropriate material laying method and arrangement procedure according to the product design, the FRP materials and structure can be completed at one time, avoiding the secondary processing usually required for metal materials, which can greatly reduce the material consumption of the product and reduce Waste of manpower and material resources.

4. Energy-saving Materials

Since many large components can be made by hand paste and do not require large and complex molds, their molding temperature is generally at room temperature or below lbo oc, so its molding and production energy consumption is very low. Even for the use of mechanical molding methods, such as molding, winding, injection, RTM, pultrusion and other molding methods, the molding temperature is much lower than that of metal and non-metal materials, so the molding energy consumption can be greatly reduced.

In summary, compared with traditional metal columns and non-metal columns, FRP colums/posts have higher strength, better performance, energy saving, greater freedom in product design, rich surface treatment methods, and suitability for production and use.