Fiberglass is a new type of synthetic material. Like other composite materials, it consists of two parts: one part is called reinforcement material, which plays a core role in the composite material; the other part is called matrix material, which plays a bonding role. The reinforcement in fiberglass is glass fiber, an inorganic material that is twice as strong as high-strength steel. There are two production processes for fiberglass sheet products, one is machine-made pultrusion production, and the other is the production by hand lay-up.

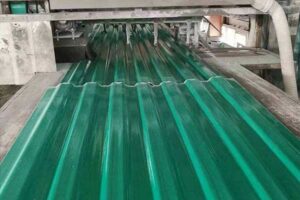

Machine-made pultruded fiberglass panels

Machine-made pultruded fiberglass panels have the following characteristics:

- Light weight

- Thermal insulation performance

- Stable surface performance

- Good permeability resistance

- Good flame retardancy

- The service life of the product is longer than that of traditional products

- Ease of maintenance: no obvious repair trace

- Good environmental performance

Hand lay-up made fiberglass panels

Hand lay-up made fiberglass panels have the following characteristics:

- Flexible production, all shapes, sizes, and thicknesses

- The price is relatively low because its production process is relatively simple, it does not need to invest much cost. Handmade, small quantities can also be customized.

- Can be made on site

Fiberglass Panels from Unicomposite

We supply Various fiberglass panels such as pultruded hollow decking, pultruded open decking, and pultruded multi-leg panel which is well-proformed. All Unicomposite’s fiberglass deckings and panels are widely used in flooring, seawall, walkways, cooling tower, vehicles, platforms, etc.