Introduction

Fiberglass molded grating trench covers have become a popular choice in industrial and commercial applications due to their durability, strength, and corrosion resistance. Unlike traditional materials like steel or aluminum, fiberglass trench covers offer a lightweight, cost-effective, and long-lasting solution for covering trenches, drains, and open channels. In this article, we will explore the benefits of using fiberglass molded grating trench covers, their various applications, and why they are considered the best choice for many businesses.

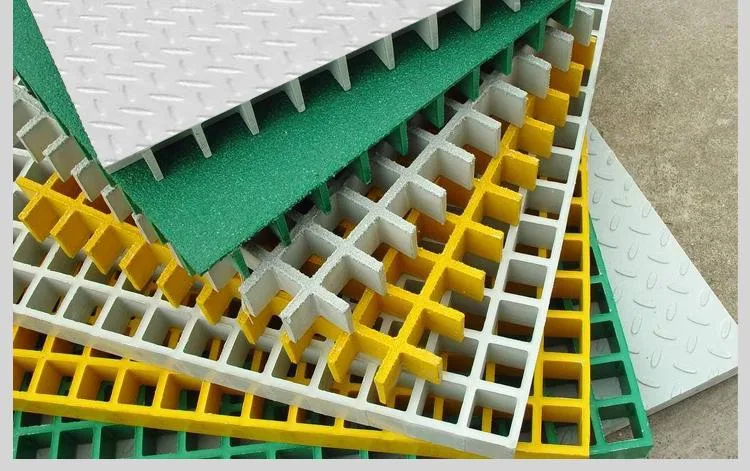

fiberglass molded grating trench cover

1. What is Fiberglass Molded Grating?

Fiberglass molded grating is a structural panel made from a resin matrix combined with fiberglass roving. The fiberglass is woven together and molded into a grid-like structure, providing exceptional strength and stability. This type of grating is available in various thicknesses, panel sizes, and mesh configurations to meet different load requirements and applications.

Key Features and Benefits:

- High Strength-to-Weight Ratio: Fiberglass grating is lightweight yet incredibly strong, making it easy to handle and install without heavy machinery.

- Corrosion Resistance: Unlike metal, fiberglass does not rust or corrode, even when exposed to chemicals, saltwater, or extreme weather conditions.

- Non-Conductive and Fire-Retardant: Fiberglass grating is non-conductive, reducing electrical hazards, and is available in fire-retardant options for added safety.

2. Why Choose Fiberglass Molded Grating Trench Covers?

Durability and Corrosion Resistance: Fiberglass molded grating trench covers are designed to withstand harsh environments and heavy loads. Their resistance to chemicals, moisture, and UV radiation ensures they remain functional and aesthetically pleasing for years, even in demanding conditions.

Lightweight and High Strength: These trench covers are much lighter than their metal counterparts, reducing the overall load on the supporting structure. Their high strength-to-weight ratio also makes them easier to install and transport, saving on labor and shipping costs.

Cost-Effectiveness and Easy Installation: The initial cost of fiberglass molded grating trench covers may be higher than traditional materials, but their longevity, low maintenance, and reduced installation costs make them a cost-effective solution in the long run.

3. Applications of Fiberglass Molded Grating Trench Covers

Fiberglass molded grating trench covers are versatile and suitable for a wide range of applications:

- Industrial Settings: Used in manufacturing plants, warehouses, and factories to cover trenches, drains, and cable ducts, providing a safe and stable walking surface.

- Commercial Buildings: Ideal for use in parking lots, sidewalks, and commercial facilities, where lightweight and durable trench covers are essential.

- Marine and Coastal Environments: Perfect for docks, marinas, and coastal walkways due to their resistance to saltwater corrosion and high humidity.

4. Comparison: Fiberglass vs. Traditional Materials for Trench Covers

While steel and aluminum are commonly used materials for trench covers, they have several drawbacks compared to fiberglass:

- Steel and Aluminum vs. Fiberglass: Steel is prone to rust and requires regular maintenance, while aluminum can corrode in certain environments. Fiberglass, on the other hand, offers superior resistance to corrosion, requires minimal maintenance, and provides a longer service life.

- Environmental Impact and Maintenance Requirements: Fiberglass trench covers have a lower environmental impact due to their longer lifespan and reduced need for replacements. They also require less maintenance, which translates to lower costs over time.

5. Choosing the Right Fiberglass Molded Grating Trench Cover

When selecting a fiberglass molded grating trench cover, several factors should be considered:

- Size and Load Requirements: Choose a trench cover that can handle the expected load, whether pedestrian traffic or heavy vehicles.

- Environmental Conditions: Consider the environmental factors such as exposure to chemicals, moisture, and UV radiation.

- Customization Options: Fiberglass molded grating can be customized in terms of color, size, and thickness to meet specific project requirements.

Conclusion

Fiberglass molded grating trench covers offer an unparalleled combination of strength, durability, and versatility, making them the ideal choice for various industrial, commercial, and marine applications. By choosing fiberglass over traditional materials, you benefit from a cost-effective, low-maintenance, and environmentally friendly solution that will stand the test of time. If you are considering trench covers for your next project, explore the many options available with fiberglass molded grating for a reliable and long-lasting investment.

Ready to upgrade your trench covers? Contact us today to learn more about fiberglass molded grating solutions!