Introduction

Industrial settings demand robust, reliable flooring solutions to ensure safety, durability, and efficiency. Among the various options available, fiberglass industrial floor grating has become a preferred choice for its unique blend of strength, safety features, and versatility. Whether you’re managing a factory floor or building a marine platform, selecting the right grating is crucial for long-term performance and safety. This guide explores the key benefits of fiberglass grating, the different types available, and how to make the best choice for your needs.

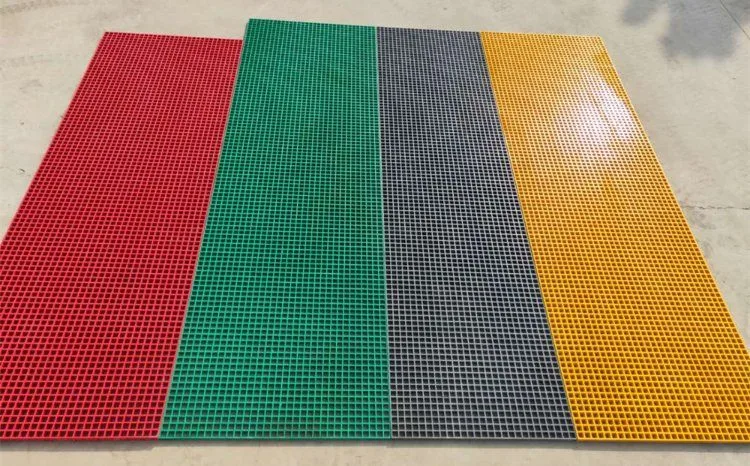

fiberglass industrial floor grating

What is Fiberglass Industrial Floor Grating?

Fiberglass industrial floor grating is a high-strength, corrosion-resistant flooring material made by combining fiberglass reinforcements with a resin matrix. Unlike traditional materials like steel or aluminum, fiberglass grating offers superior resistance to harsh environments while remaining lightweight and easy to install.

- Compared to Steel: Fiberglass is non-corrosive and requires little maintenance, unlike steel, which is prone to rust in wet or chemical-laden environments.

- Compared to Aluminum: Fiberglass provides better chemical resistance and is non-conductive, making it safer for electrical applications.

Its unique properties make it ideal for industries like chemical processing, water treatment, and marine construction.

Key Benefits of Fiberglass Industrial Floor Grating

Durability and Longevity

Fiberglass grating is engineered to withstand harsh conditions, including exposure to chemicals, moisture, and UV rays. Its corrosion-resistant properties ensure a long lifespan with minimal maintenance, making it a cost-effective solution for industrial environments.

Enhanced Safety Features

Safety is a top priority in industrial settings, and fiberglass grating excels in this area:

- Slip Resistance: Available with grit-top surfaces for superior traction, even in wet or oily conditions.

- Non-Conductive: Unlike metal grating, fiberglass does not conduct electricity, reducing risks in electrical environments.

Lightweight and Easy Installation

Fiberglass grating is significantly lighter than steel, making it easier to handle, transport, and install. This reduces labor costs and allows for quicker installations without heavy equipment.

Types of Fiberglass Industrial Floor Grating

Molded Fiberglass Grating

This type of grating is created in a single-piece construction, offering excellent strength and flexibility.

- Applications: Ideal for environments with frequent exposure to moisture or chemicals, such as wastewater treatment facilities.

- Advantages: Lightweight, corrosion-resistant, and easy to fabricate.

Pultruded Fiberglass Grating

Pultruded grating is manufactured through a process that aligns fiberglass strands in a specific direction, resulting in high load-bearing capacity.

- Applications: Perfect for heavy-duty areas like industrial platforms and walkways.

- Advantages: Stronger than molded grating for applications requiring higher strength-to-weight ratios.

Custom Grating Options

For unique industrial needs, custom fiberglass grating can be tailored to specific dimensions, colors, and surface finishes. This ensures optimal performance for specialized applications.

How to Choose the Right Fiberglass Grating

Evaluate Load-Bearing Requirements

Determine the weight the grating will need to support. For heavy machinery or frequent foot traffic, opt for pultruded grating with a high load capacity.

Consider Environmental Conditions

Analyze the environmental factors your grating will face, such as exposure to chemicals, moisture, or temperature extremes. Fiberglass grating is designed to perform well in corrosive and wet conditions, but choosing the right resin type (e.g., vinyl ester for chemical resistance) is critical.

Prioritize Safety Features

For areas prone to slipping, select grating with a grit-top surface or embedded slip-resistant features. Non-conductive properties are essential in electrical environments to enhance worker safety.

Assess Longevity and Maintenance Needs

While fiberglass grating may have a higher upfront cost than traditional materials, its durability and low maintenance make it a long-term investment. Ensure the grating meets your lifecycle expectations.

Tips for Maintaining Fiberglass Industrial Floor Grating

To maximize the lifespan of your fiberglass grating:

- Clean Regularly: Use non-abrasive cleaning agents to remove dirt, grease, and chemical residues.

- Inspect Periodically: Check for signs of wear, cracks, or loose fasteners, and address any issues promptly.

- Repair or Replace: Damaged sections should be repaired or replaced to maintain safety and functionality.

Conclusion

Fiberglass industrial floor grating offers unparalleled benefits in terms of durability, safety, and versatility, making it a smart choice for industrial and commercial environments. By understanding your application requirements, environmental conditions, and safety needs, you can select the perfect grating to meet your needs.

Ready to upgrade your industrial flooring? Consult a professional supplier to explore tailored fiberglass grating solutions for your facility today.