The construction industry is constantly evolving, with new materials and technologies emerging to enhance the performance and longevity of structures. One such innovation that has gained popularity in recent years is Kodiak fiberglass rebar. This revolutionary construction material offers a multitude of advantages over traditional steel rebar, making it a preferred choice for engineers, architects, and contractors. In this article, Unicomposite composite profiles will explore seven key benefits of Kodiak fiberglass rebar that you need to know.

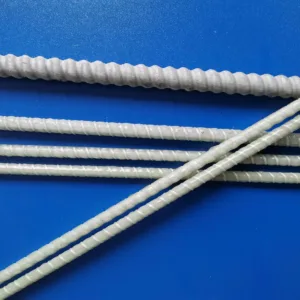

kodiak fiberglass rebar

1. Lightweight and Easy to Handle

Kodiak fiberglass rebar is exceptionally lightweight compared to its steel counterpart. This characteristic simplifies the transportation and installation process significantly. Construction workers can handle and maneuver the fiberglass rebar with ease, reducing the need for heavy machinery and resulting in cost savings on labor. Additionally, the reduced weight minimizes the strain on workers, promoting a safer working environment.

2. Corrosion Resistance and Durability

Traditional steel rebar is susceptible to corrosion when exposed to moisture and certain chemicals. Kodiak fiberglass rebar, on the other hand, is inherently resistant to corrosion, ensuring that the structural integrity of the concrete remains intact over time. This durability translates into a longer lifespan for the reinforced concrete structures, reducing the frequency of maintenance and repair work.

3. High Strength-to-Weight Ratio

Despite being lightweight, Kodiak fiberglass rebar boasts a high strength-to-weight ratio, offering exceptional tensile strength. This property allows it to withstand heavy loads and seismic forces, making it ideal for construction in earthquake-prone areas. The combination of strength and low weight makes it a reliable and efficient reinforcement material for a wide range of projects.

4. Thermal Insulation Properties

Unlike steel rebar, which conducts heat and cold, Kodiak fiberglass rebar exhibits excellent thermal insulation properties. This characteristic helps in maintaining a more stable internal temperature of the concrete, which is particularly advantageous in extreme weather conditions. Structures reinforced with fiberglass rebar are better equipped to handle temperature fluctuations, reducing the risk of cracks and ensuring long-term structural integrity.

5. Non-Conductive Material

An essential benefit of Kodiak fiberglass rebar is its non-conductive nature. Unlike steel, it does not conduct electricity, which is particularly beneficial for projects involving electrical components or in areas prone to lightning strikes. The non-conductive property of fiberglass rebar provides an added layer of safety, reducing the risk of electrical accidents.

6. Cost-Effective Solution

While the upfront cost of Kodiak fiberglass rebar may be higher than traditional steel rebar, its long-term cost-effectiveness becomes apparent. As previously mentioned, its resistance to corrosion and extended durability result in reduced maintenance and repair expenses. Moreover, the ease of handling and installation speeds up the construction process, further contributing to cost savings.

7. Versatility in Applications

Kodiak fiberglass rebar finds application in various construction projects, from highways and bridges to marine structures and buildings. Its versatility stems from its ability to withstand harsh environments, including exposure to chemicals, saltwater, and extreme temperatures. Whether it’s a coastal structure or an inland building, Kodiak fiberglass rebar proves to be a reliable and versatile reinforcement solution.

Sustainability and Environmental Benefits

In an era of increased focus on sustainable construction practices, Kodiak fiberglass rebar shines as an environmentally friendly alternative to steel rebar. The production of fiberglass rebar consumes less energy and emits fewer greenhouse gases, reducing its carbon footprint. Additionally, its long lifespan and recyclability further contribute to a greener construction industry.

Comparison with Traditional Steel Rebar

Let’s compare Kodiak fiberglass rebar with traditional steel rebar:

- Weight: Fiberglass rebar is lighter, making it easier to transport and install.

- Corrosion Resistance: Fiberglass rebar does not rust or corrode, unlike steel rebar.

- Strength: Both materials offer high strength, but fiberglass rebar has a better strength-to-weight ratio.

- Thermal Conductivity: Steel rebar conducts heat and cold, while fiberglass rebar provides thermal insulation.

- Electrical Conductivity: Steel rebar conducts electricity, while fiberglass rebar is non-conductive.

- Cost: Fiberglass rebar may have a higher upfront cost, but its long-term cost-effectiveness offsets this.

Installation Process and Safety Measures

The installation process of Kodiak fiberglass rebar is similar to that of traditional steel rebar, with minor adjustments to accommodate its unique properties. Contractors and construction teams must follow safety guidelines to ensure proper handling, cutting, and securing of fiberglass rebar. Safety measures include wearing appropriate personal protective equipment (PPE) and using specialized tools designed for fiberglass reinforcement.

Maintenance and Longevity

Due to its exceptional resistance to corrosion and degradation, Kodiak fiberglass rebar requires minimal maintenance compared to steel rebar. This advantage significantly extends the service life of reinforced structures, reducing maintenance costs and potential disruptions to daily operations.

Case Studies and Real-Life Applications

Numerous construction projects worldwide have successfully implemented Kodiak fiberglass rebar. For example:

- Highway Overpasses: Fiberglass rebar has been utilized in the construction of highway overpasses, where its lightweight nature reduces the load on support structures while maintaining strength.

- Marine Structures: In coastal regions where steel rebar is prone to corrosion, fiberglass rebar offers a durable and long-lasting solution for marine structures like docks and piers.

- Bridge Decks: The thermal insulation properties of fiberglass rebar are advantageous in bridge decks, preventing cracking due to temperature fluctuations.

- Parking Garages: The non-conductive property of fiberglass rebar makes it a safe choice for parking garages, reducing the risk of electrical incidents.

Frequently Asked Questions

- Q: Is Kodiak fiberglass rebar more expensive than steel rebar?

- A: While the initial cost may be higher, the long-term cost-effectiveness of fiberglass rebar makes it a viable investment.

- Q: Can Kodiak fiberglass rebar replace steel rebar in all applications?

- A: While fiberglass rebar is versatile, certain specialized applications may still require steel reinforcement.

- Q: Does Kodiak fiberglass rebar require special handling during installation?

- A: Yes, contractors should follow safety guidelines and use appropriate tools when working with fiberglass rebar.

- Q: How long does Kodiak fiberglass rebar last in comparison to steel rebar?

- A: Due to its corrosion resistance, fiberglass rebar can last significantly longer than steel rebar.

- Q: Is Kodiak fiberglass rebar eco-friendly?

- A: Yes, fiberglass rebar has a lower carbon footprint and is recyclable, making it an environmentally friendly choice.

Conclusion

Kodiak fiberglass rebar is revolutionizing the construction industry with its exceptional benefits. Its lightweight, corrosion resistance, high strength, thermal insulation properties, and non-conductive nature make it a superior alternative to traditional steel rebar. The cost-effectiveness, versatility, and sustainability of Kodiak fiberglass rebar make it an excellent choice for a wide range of construction projects. Embracing this innovative material not only enhances structural performance but also contributes to a greener and more sustainable future for the construction industry.