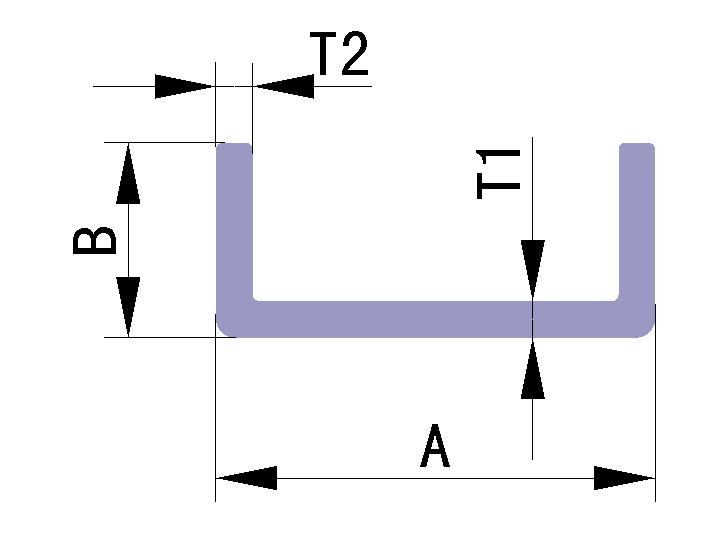

Fiberglass Channels Available:

| Fiberglass Channel | |||

| A(inch) | B(inch) | T1(inch) | T2(inch) |

| 0.71 | 0.31 | 0.06 | 0.06 |

| 0.91 | 0.98 | 0.12 | 0.12 |

| 1.29 | 1.12 | 0.12 | 0.12 |

| 1.31 | 0.79 | 0.12 | 0.12 |

| 1.38 | 0.33 | 0.10 | 0.10 |

| 1.77 | 1.26 | 0.10 | 0.16 |

| 1.80 | 1.68 | 0.10 | 0.10 |

| 49.8 | 19.3 | 0.10 | 0.10 |

| 2.20 | 2.09 | 0.12 | 0.12 |

| 2.32 | 0.75 | 0.10 | 0.10 |

| 3.22 | 0.99 | 0.16 | 0.16 |

| 3.29 | 1.18 | 0.14 | 0.20 |

| 3.39 | 1.30 | 0.16 | 0.16 |

| 3.39 | 1.18 | 0.28 | 0.31 |

| 3.39 | 1.22 | 0.16 | 0.20 |

| 3.54 | 1.02 | 0.25 | 0.10 |

| 3.75 | 1.5 | 0.10 | 0.10 |

| 3.94 | 1.97 | 0.25 | 0.25 |

| 3.94 | 3.82 | 0.12 | 0.12 |

| 4.02 | 1.14 | 0.25 | 0.25 |

| 4.02 | 1.38 | 0.19 | 0.19 |

| 4.72 | 1.97 | 0.24 | 0.24 |

| 5 | 1.38 | 0.26 | 0.26 |

| 5.99 | 1.61 | 0.25 | 0.25 |

| 6.10 | 0.96 | 0.15 | 0.15 |

| 6.10 | 1.57 | 0.37 | 0.37 |

| 7.40 | 3.54 | 0.31 | 0.31 |

| 7.87 | 1.97 | 0.39 | 0.39 |

| 7.87 | 2.36 | 0.39 | 0.39 |

| 7.99 | 2.17 | 0.25 | 0.25 |

| 9.45 | 2.83 | 0.31 | 0.31 |

| 9.84 | 2.12 | 0.16 | 0.16 |

| 9.84 | 4.92 | 0.39 | 0.39 |

| 10.04 | 2.95 | 0.5 | 0.5 |

| 11.81 | 3.94 | 0.39 | 0.39 |

| 19.67 | 2.36 | 0.39 | 0.39 |

Fiberglass Channels Available:

| Fiberglass Channel | |||

| A(mm) | B(mm) | T1(mm) | T2(mm) |

| 18 | 8 | 1.5 | 1.5 |

| 23 | 25 | 3 | 3 |

| 31.5 | 28.5 | 3 | 3 |

| 33.4 | 20 | 3 | 3 |

| 35 | 8.4 | 2.5 | 2.5 |

| 45 | 32 | 2.5 | 4 |

| 45.5 | 42.5 | 2.5 | 2.5 |

| 49.8 | 19.3 | 2.5 | 2.5 |

| 56 | 53 | 3 | 3 |

| 59 | 19 | 2.5 | 2.5 |

| 82 | 25 | 4 | 4 |

| 83.5 | 30 | 3.5 | 5 |

| 86 | 33 | 4 | 4 |

| 86 | 30 | 7 | 8 |

| 86 | 31 | 4 | 5 |

| 90 | 26 | 6.3 | 2.5 |

| 95.2 | 38.1 | 2.5 | 2.5 |

| 100 | 50 | 6.4 | 6.4 |

| 100 | 97 | 3 | 3 |

| 102 | 29 | 6.4 | 6.4 |

| 102 | 35 | 4.8 | 4.8 |

| 120 | 50 | 6 | 6 |

| 127 | 35 | 6.5 | 6.5 |

| 152 | 41 | 6.4 | 6.4 |

| 155 | 24.5 | 3.8 | 3.8 |

| 155 | 40 | 9.5 | 9.5 |

| 188 | 90 | 8 | 8 |

| 200 | 50 | 10 | 10 |

| 200 | 60 | 10 | 10 |

| 203 | 55 | 6.35 | 6.35 |

| 240 | 72 | 8 | 8 |

| 250 | 54 | 4 | 4 |

| 250 | 125 | 10 | 10 |

| 255 | 75 | 12.7 | 12.7 |

| 300 | 100 | 10 | 10 |

| 500 | 60 | 10 | 10 |

Many additional sizes are available.

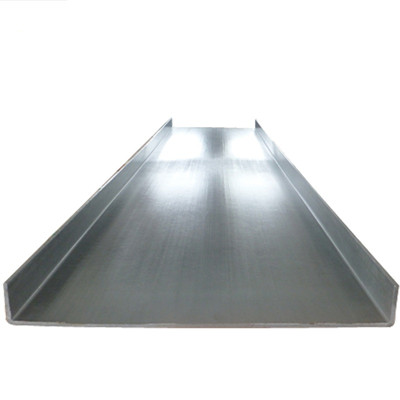

Pultruded fiberglass channels are particularly useful in applications in which metals can’t provide an ideal solution,

e.g., where corrosion is a concern or lightweight structural shapes are required for easy installation

One of the most common applications of fiberglass strut channels is in harsh environment which are subject to chemical

exposure. Some of these are such as outdoor walkways, water treatment plants, among others.

They are also used in several outdoor activities such as in arrow shaft, crossbows, paddle shafts, hocky stick, golf

shaft, kick board among others.

- fiberglass channel

- fiberglass channel

- fiberglass channel