We start to custom design and manufacture once our company was found, and now we have lots of successful cases in offering support to our customers on the projects and application. We are striving to serve our customs with best service and qualified products in the following ways:

■ Cost and quicker delivery: We can design and manufacture the moulds and tools for the FRP profiles, so our total price is lower than that supplied by those suppliers who need to buy the mould from others. Also we can guarantee a much quicker delivery, saving the time for our customer.

■ Material used: standard resin systems can meet different requirements and applications (polyester resin, vinyl ester resin, epoxy resin, phenolic and blend )

■ Reinforcements: Giving the proper advice on the reinforcements to use, and the typical ones are glass fiber or

■ Shapes: from simple to complex, we can supply the pultrusion products with different shapes by vary techniques

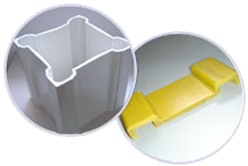

Large to Small

Large to Small

Unicomposite produces large as well as small profiles. And all profiles can be produced in any transportable length.

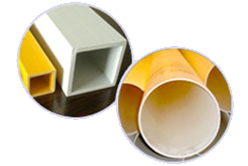

Thick to Thin

Thick to Thin

Unicomposite can manufacture the pultrusion products with various of wall thickness.

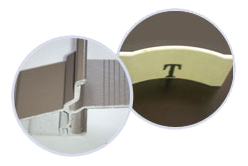

Complex to Simple

Complex to Simple

Unicomposite’s production range from multi-cavity, thin-walled, close tolerance parts as window profiles to simple rods, angles or tubes.

Unicomposite has the R&D department and professional technology support team.

For any information needed, please don’t hesitate to contact our technology department.

Products and Details

Please contact us to get more information about custom pultrusions.